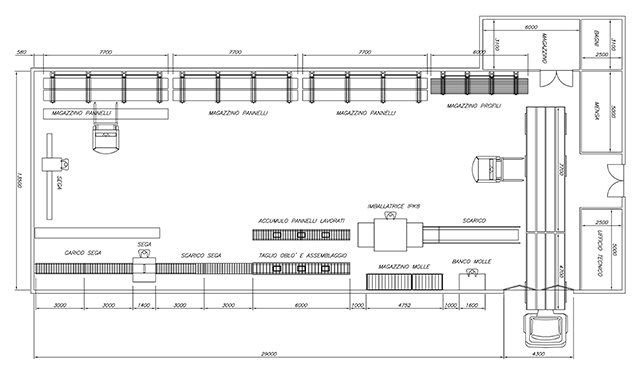

A complete assembly line has been designed and built for a well-known Italian company for residential and industrial sectional doors

The result of our twenty-year experience in the sector, the line consists of:

1) loading roller conveyor

2) circular saw for transversal and longitudinal cutting of the panels, with motorized stop and programmable cutting dimensions;

3) unloading roller conveyor

4) assembly bench, with mobile trolleys for the execution of the pre-drilling of the lateral and intermediate hinges and porthole cutting island and pedestrian door (with cutting shaving aspirator);

5) Re-packaging of packaging preparation

6) rotary packing machine

The line is designed to allow the door to be processed by a single operator.

It is possible to work panels of the main producers such as: Marcegallia, Italpannelli, Epco, Kingspan, etc., in sizes from 500 and 610 and in the thickness of 40 mm.

The production cycle is simple to implement and control.

The pack of the machined panels, appropriately spaced with polystyrene plates, together with the overall guides, axis and balancing springs, are packaged together forming a single package for shipping.

For more details and personalized studies please contact us.

Here is a video of the aforementioned assembly line.