TEST TUV 2016

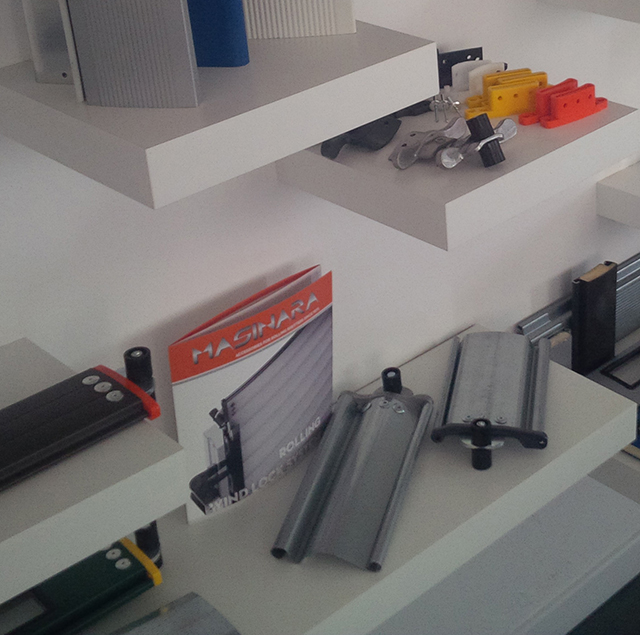

The MASINARA company, of Monteveglio (BO), carried out wind resistance tests on the “rolling system”,

in combination with the the most popular shutters profiles, tested at 9 and 12 meters widts (never tested before).

The tests were carried out by the prestigious European certification laboratory: TUV Nord Germany, according to the method test required by UNI EN 12444.

The following table shows the models, materials and results obtained.

| POS | TIPO | MODELLO | PASSO | SPESSORE | FINITURA | CLASSE | LARGHEZZA |

| VENTO | LUCE | ||||||

| CERTIFICATA | mt | ||||||

| 1 | MONO | P115 | 114 | 8/10 | ACCIAIO ZINCATO | +/- 2 | 12 |

| 2 | MONO | P115 | 114 | 7/10 | ACCIAIO BUGNATO | +/- 2 | 12 |

| 3 | MONO | P115 | 114 | 12/10 | ALLUMINIO BUGNATO | +/- 2 | 9 |

| 4 | MONO | P97 | 97 | 8/10 | ACCIAIO ZINCATO | +/- 1 | 12 |

| 5 | MONO | P97 | 97 | 7/10 | ACCIAIO BUGNATO | ROTTURA 262 | 12 |

| 6 | MONO | P97 | 97 | 12/10 | ALLUMINIO BUGNATO | ROTTURA 247 | 12 |

| 7 | DOPPIO | DP77 Perasole | 77 | 5/10 | ACCIAIO PLASTIFICATO | +/- 2 | 12 |

| 8 | DOPPIO | DP77 Perasole | 77 | 5/10 | ALLUMINIO PLASTIFICATO | +/- 2 | 9 |

| 9 | DOPPIO | DP90 Biorol | 90 | 5/10 | ACCIAIO ZINCATO | +/- 2 | 12 |

| 10 | DOPPIO | DP95 Taraborelli | 95 | 6+4/10 | ACCIAIO PREVERNICIATO | +/- 2 | 12 |

| 11 | DOPPIO | DP95 Taraborelli | 95 | 6+6/10 | ALLUMINIO PREVERNICIATO | +/- 1 | 12 |

The resistance values for smaller widths will be obtained by linear interpolation on graphs present in the “test report” issued by the TUV.

The resistance classes comply with UNI EN 12424 and can be indicated in the DoP certification (CPR 305-2011) issued by the manufacturers of rolling shutters with cascading contract, issued by the MASINARA company of Monteveglio (BO).

|  |  |

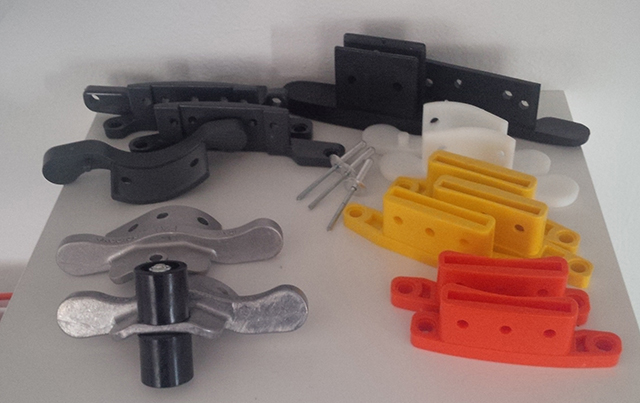

The resistance tests of the mooving brackets SG85 (from 7.5 kN) and SG115 (from 115 kN) were carried out in the laboratory of the Mechanical Engineering Department of the Polytechnic of Bari, in the presence of the TUV Nord Germany. The mooving brackets were largely within the safety limits established by UNI EN 12604.

|  |

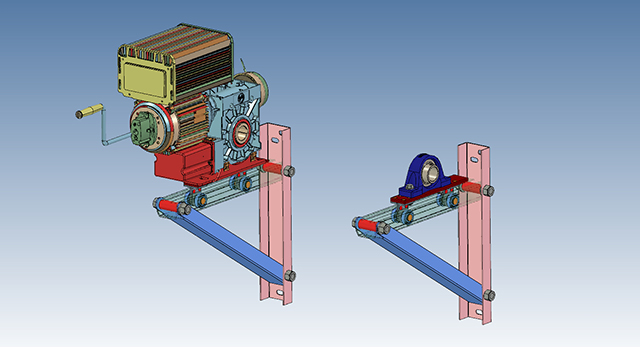

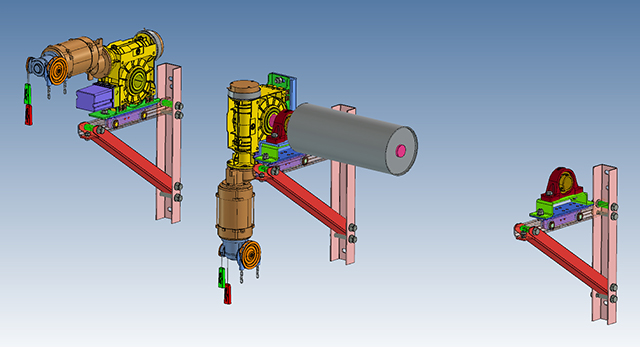

The design of all the components was taken care of by Piumelli Pantaleo (PIUTEK) – Bisceglie (BT).

The design and construction of the test benches and the support for carrying out the tests was provided by the company BLM Costruzioni Meccaniche di Conversano (BA).

The construction and marketing of the components (patented) will be carried out by the company Masinara of Monteveglio (BO).